THE FUTURE OF COPPER

The transition towards a sustainable and electrified model of the world will result in an increased demand for copper.

By 2050, demand is forecast to double, rising to 60M tonnes. Currently, there is a demand for over 30M tonnes of copper and only 9.8M tonnes are recycled, representing just over 30% of annual copper use.

Consumers and markets no longer demand the same and recycled copper has acquired a key role in facing the increased demand for environmentally friendly products.

Electrification

Renewable Energy

Automotive and E-mobility

Digitalization

Metal Packaging

Construction and Installations

Rail Infrastructure

Magnet Wire

COPPER, ENDLESSLY RECYCLABLE

Copper is a metal with multiple attributes that make it a unique and essential material.

For every tonne of recycled copper processed, the emission of 3.9 tonnes of CO2 is directly saved:

Which is equivalent to 2 combustion engine cars per year

Or what

130 trees can absorb in a year

Copper can be reused over and over again.

Endless recyclability without losing properties is one of its most valued natural characteristics.

1

2

Copper is the most conductive metal after silver.

Therefore, it offers the best solutions for electrical and thermal conductivity.

Copper is antimicrobial, the only metal certified by the EPA as a bactericide.

The ability to withstand sudden increases in temperature makes it a safe and healthy choice.

3

4

Copper is a durable material.

Ductile and versatile with high resistance to corrosion.

There are copper alloys that allow its qualities to be improved.

We can thus attain the levels required by some applications that the market requests.

5

Copper is found in many forms in our daily lives and in most of the everyday objects we use every day.

WE CONTRIBUTE TO

THE DECARBONISATION

OF THE PLANET AND THE ECONOMY

THE DECARBONISATION

OF THE PLANET AND THE ECONOMY

At La Farga we are aware of the environmental impact of industry, but it is also true that our activity is essential for human development and for the energy transition, given that a significant part of the latter consists of electrification and the development of renewable energies, for which copper is an indispensable material.

One of our values is innovation, and since our beginnings we have invested and worked to put innovation at the service of sustainability, incorporating technologies that allows us to reduce emissions throughout the value chain and work more efficiently. Our solutions are necessary for the energy transition, copper coupled the development of in-house technology contributes both directly and indirectly to the decarbonisation of the economy.

The main goal of the Decarbonisation Plan created by La Farga is to reduce GHG emissions into the atmosphere by 55% (compared to 2019) by 2030.

And our 2050 goal is to achieve the NetZero targets with minimal offsetting of greenhouse gas emissions produced by our activity.

The main focuses of the plan are:

1

Improving efficiency

Some of the actions included are the reduction of the amount of energy needed per tonne processed, obtaining the ISO 50001 standard and the recovery of residual heat and fumes.

2

Use of alternative fuels

It consists of replacing natural gas with alternative renewably sourced fuels, in this respect we are studying several alternatives.

3

Electrification and renewable energies

It consists of electrifying processes, machinery and encouraging the use of electric energy from renewable sources. The installation of solar panels and improvements in the hydroelectric power plant are included in the plan.

4

Genius

It consists of introducing GENIUS solutions into all copper applications, because it is the most sustainable copper on the market, made 100% from recycled copper and with the lowest carbon footprint.

2030 OBJECTIVE

TO REDUCE GHG EMISSIONS BY OVER 55%

100% OF THE ELECTRICAL POWER THAT WE CONSUME IS RENEWABLE.

IN 2023 WE REDUCED CO2 BY 16,476.4 TN WHICH IS EQUIVALENT TO PLANTING 659,056 TREES

*Certificate of guarantees of renewable origin (GOs) in accordance with the consumption of 100% renewable energy, ISO 50001

La Farga is copper, copper is La Farga

Discover the long history of La Farga and how, over the years, we have driven the transformation of the world and industry in order to have a positive impact on people and the planet.

La Farga is copper, copper is La Farga

Discover the long history of La Farga and how, over the years, we have driven the transformation of the world and industry in order to have a positive impact on people and the planet.

-

2023

ISO 50001 Energy Efficiency Certification.

Our commitment to the planet and society is what drives us to work to reduce the environmental impact of our products and processes, and to also care for and improve the social conditions of our operations, in order to have a positive impact that enables the sustainable development of our company.

-

2023

Generational handover of LA FARGA.

Consolidation of the generational handover process, the process has lasted for a few years following the family protocol, one of the cornerstones of the company’s governance, and addressing the challenges of the family business.

-

2022

Launch at La Farga of the first 100% recycled copper contact wire

Launch at La Farga of the first 100% recycled copper contact wire and with the smallest carbon footprint for rail infrastructure.

-

2020

GENIUS, the most sustainable copper wire rod on the market, 100% recycled and the smallest carbon footprint.

We are the first company in the sector to offer a 100% recycled copper product and with the lowest CO2 emission impact certified by an Environmental Product Declaration (EPD complies with the standards of ISO 14025 and EN 15804). The EPD proves that its environmental impact is much smaller than that of the mine production of copper.

-

2018

Corporate merger of the different group companies.

The different group companies merged into a single company La Farga Yourcoppersolutions, accompanied by a reorganisation of the organisation chart to pursue efficiency and transversality.

-

2018

Corporate merger of the different group companies.

The different group companies merged into a single company La Farga Yourcoppersolutions, accompanied by a reorganisation of the organisation chart to pursue efficiency and transversality.

-

2014

Investment in improving production plant.

Renewal of the Refining oven with proprietary technology with the benefit of energy reduction, greater productivity and maximum efficiency.

-

2012

Investment in Evotub.

Development of proprietary technology, successful development and innovation.

-

2011

SDI La Farga opened in the United States.

Consolidation of the international expansion process, creating a company in the United States, SDI Ls Farga, for the creation of recycled copper wire rod.

-

2010

International Expansion.

Strategic expansion of our technology and copper processing in China and the United States

-

2008

Opening of Copper Museum

To mark the celebration of the bicentenary of the creation of La Farga. The Copper Museum is located in the premises of La Farga, in an old modernist building dating back to the beginning of the 20th century.

-

2008

Business expansion

With a major investment and start of the production of electrolytic wire rod.

-

2008

Bicentenary of the company

In 2008 La Farga Lacambra celebrated 200 years of history. The book “Copper solutions since 1808” was published.

-

2007

First Sustainability Report on LF and the sector.

La Farga positions itself as a benchmark company showcasing the sector and product.

-

2006

La Farga Group.

Company’s name change and joining the United Nations Compact. We are a company with a purpose, “Maximising the use of recycled copper and the technologies that have made it possible.” Our commitment and responsibility towards that purposes reaffirms our loyalty to the principles of the United Nations Global Compact and the Sustainable Development Goals (SDGs).

-

2004

Consolidation on international rail market.

New range of products for the rail electrification sector.

-

1990

Creation of La Farga Tub and opening of new copper tube factory in 1992

Creation of La Farga Tub and opening of new copper tube factory in 1992

-

1986

La Farga launches world’s first continuous casting with recycled copper.

Development of thermal wire rod for continuous casting and patent obtained for the process, whose technology was sold to countries in different continents.

-

1981

Entry of Fisas and Guixà families as owners of LA FARGA

Entry of Fisas and Guixà families as owners of LA FARGA

-

1960

Specialisation in the electrical cables market

The electrical industry and rail sector would become the main markets for La Farga over the following decades.

-

1913

Start of Copper Rod production

La Farga undertook a major renewal of machinery that enabled it to begin the production of wire rod for electrical cables in 1913.

-

1852

La Farga Lacambra

Francesc Lacambra built a forge on the banks of the River Ter in Les Masies de Voltregà, with the aim of harnessing the strength of the water to produce copper sheeting. La Farga began production of sheeting at the end of the summer of 1853.

-

1808

Creation of LA FARGA

That year, Francesc Lacambra Pont created a small family-run foundry in the port neighbourhood of La Barceloneta, devoted to the production of copper and bronze products for the Catalan navy.

- 2023

- 2023

- 2022

- 2020

- 2018

- 2018

- 2014

- 2012

- 2011

- 2010

- 2008

- 2008

- 2008

- 2007

- 2006

- 2004

- 1990

- 1986

- 1981

- 1960

- 1913

- 1852

- 1808

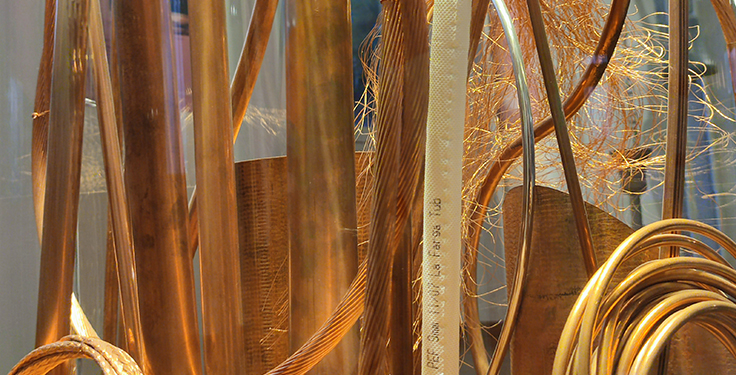

THE COPPER MUSEUM

La farga is past, present and future

The Copper Museum is an opportunity to present the history of this noble metal and La Farga to society. Two stories told in a cultural and training space that enable us to understand an industry and an innovation model that has transformed society over the years.

It is located in the facilities of La Farga, in an old modernist building dating back to the early 20th century. It was opened in 2008 to mark the celebration of the bicentenary of the founding of La Farga and since then it has been for the people of La Farga and its area, an emblematic place where knowledge about copper becomes reality.

The concept, design and structure of the museum were possible thanks to the cooperation between La Farga Foundation and the University of Vic, which took on the management of the museological and museographic project.

A visit to the museum allows visitors to see the history of the company, the origins of copper, the characteristics of the metal and the technology linked to it. It also includes a visit to the La Farga production plant, which enables the public to get a first-hand look at industrial activity.

The museum’s main audience is school groups; therefore a teaching plan is offered for them, tailored to the level of the pupils, from primary education up to visits from universities and courses.

+45.337

visits since 2008

The collection